Assembly and check-test stations

Our company develop, design and manufacture assembly fixtures and check stations build into automated assembly workstation. The main advantage of workstation is instant or consecutive test of assembled part at one place.

Few advantages when using assembly fixtures and check stations build in automated assembly workstation:

- assembly tact time reduction

- assembly quality increase

- reduction of produced “reject” parts

- simplification of complicated assembly operations

- chance of job-related injuries reduction

- possibility of instant quality check

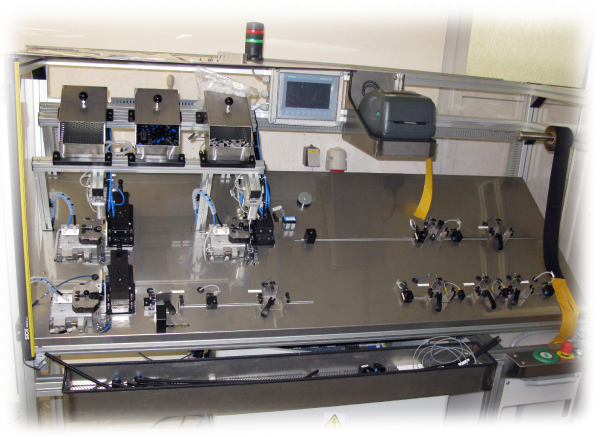

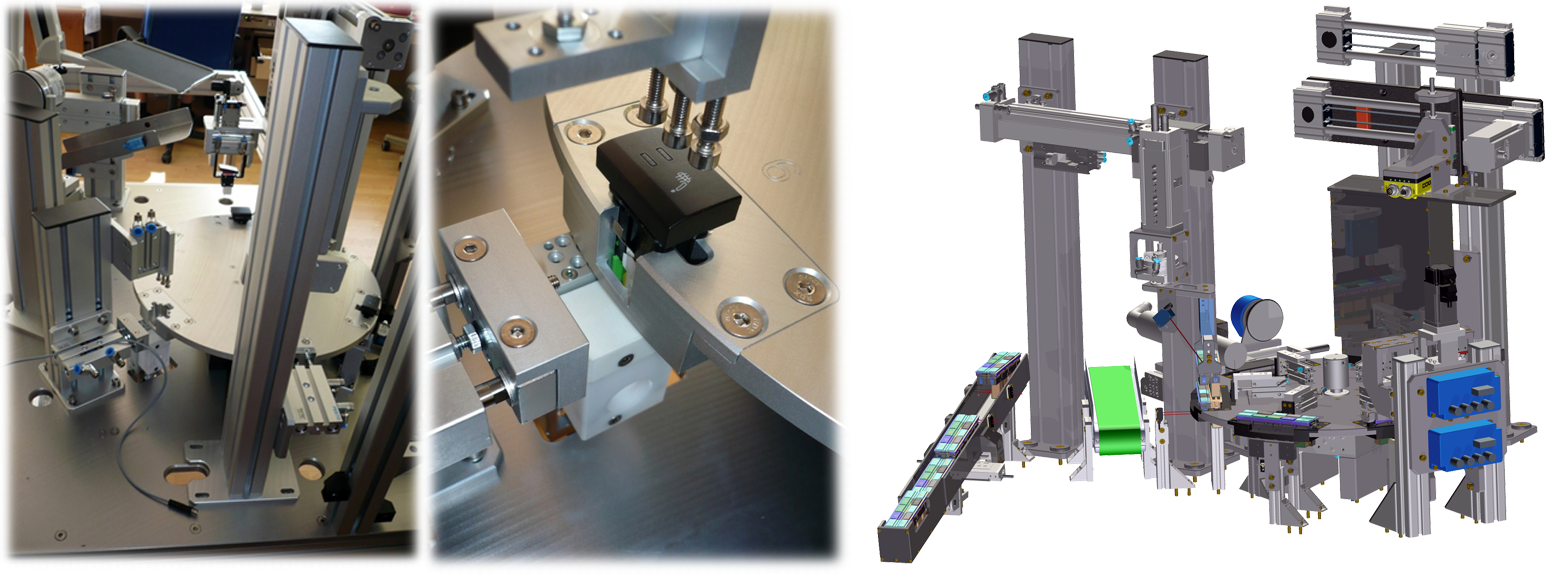

EOLT Cushion- assembly and check station of a seat

Station checks the dimensions of manufactured product according to specified tolerances.

For example: diameter of ISOFIX wire tolerance 0,1mm, Coaxiality check, and weld position check. Next test is Bowden cable test of exact extension and insertion measured by linear potentiometer.

Positioning of wire is carried out by servodrive.

Markings as serial number and code is manufactured by punching tool.

Part of the station equipment is a phased torque tool.

Station is equipped with cameras to be ableto check the presence and dimensions of manufactured parts.

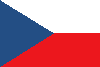

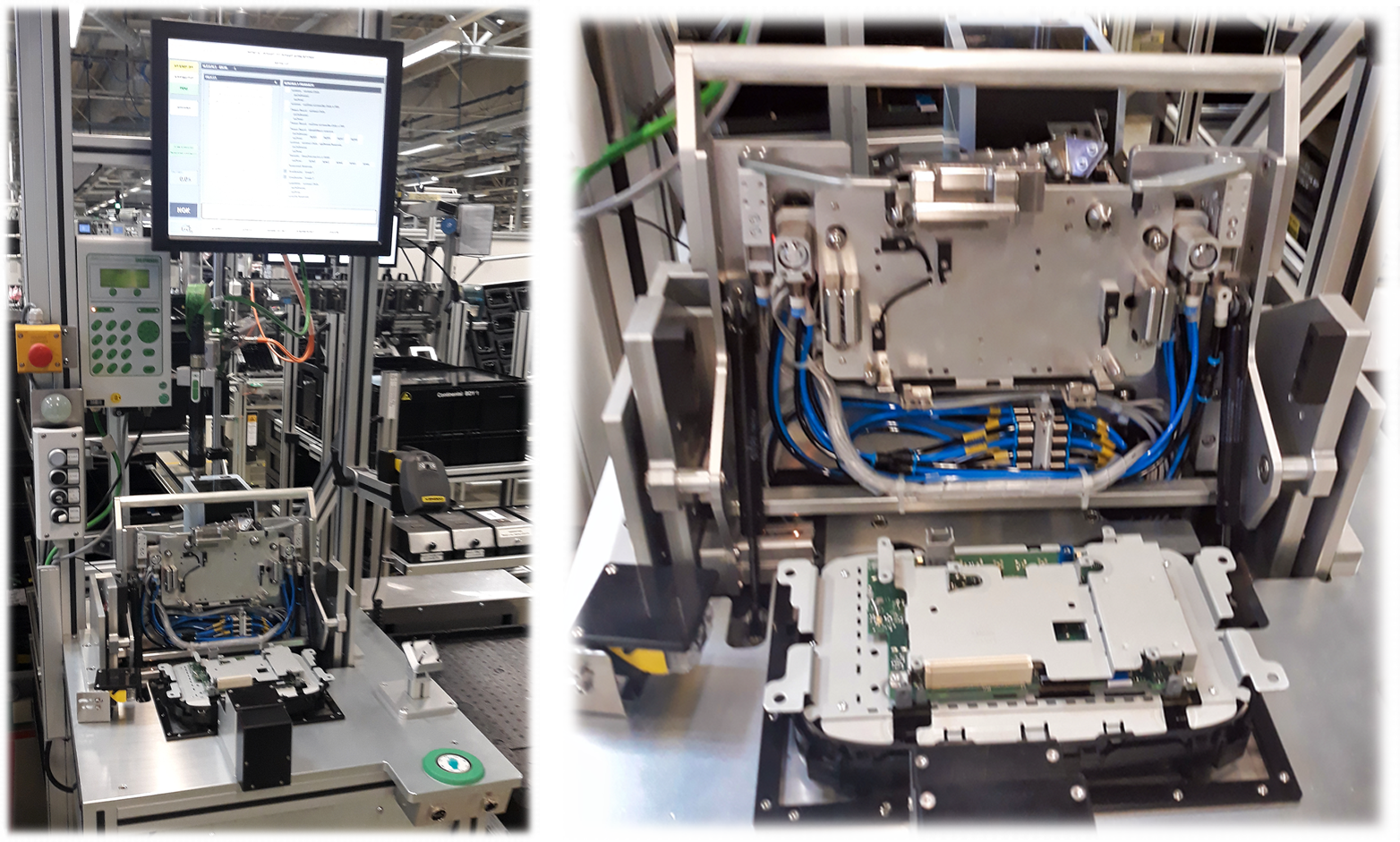

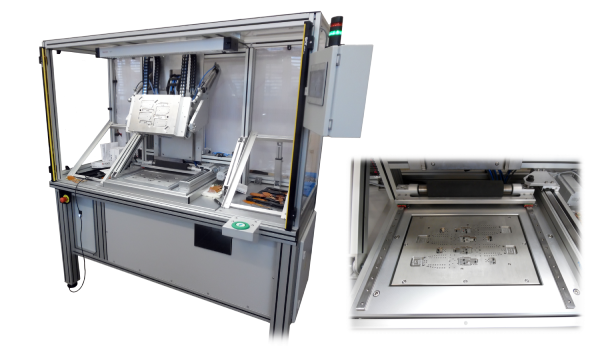

EMC/EMI shielding covers assembly workstation for DPS (example).

- Workstation providing precise guidance of DPS and connection with pin terminal.

- Individual fixtures are equipped with precise guidance mechanism, pneumatic feed and reduced force.

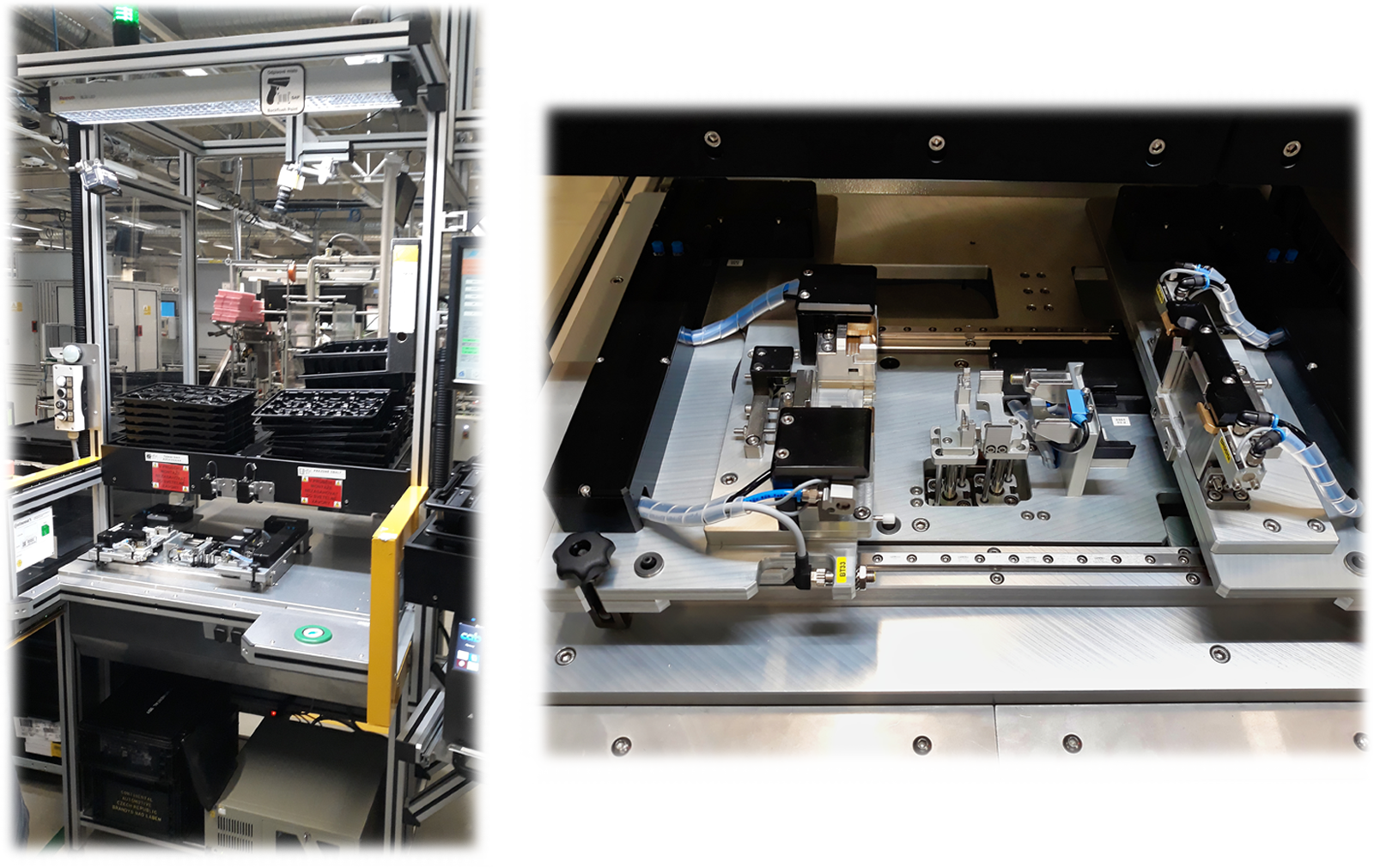

Semi automatic assembly station of board to board connector

- station secures and sets the exact guidance of the DPS and precise contacting with the connector

- individual collators are equipped by precise pneumatic drive guidance machanism with reduced force

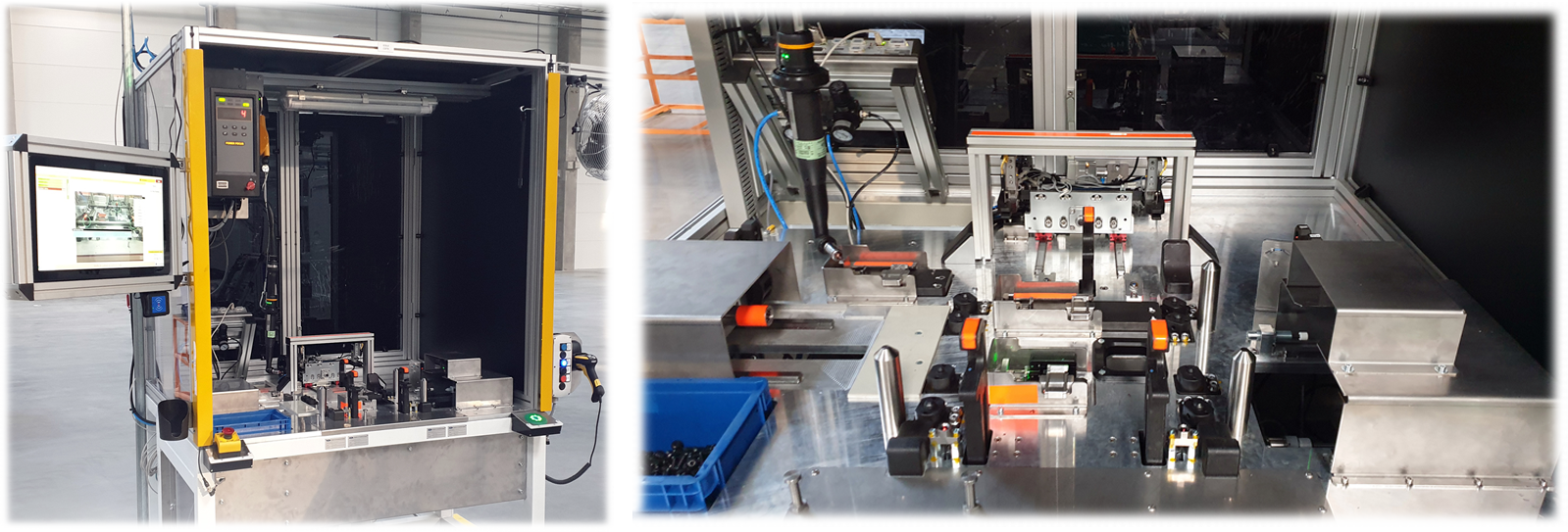

Assembly workstation for USB HUB assembly

- exchangeable fixtures for 5 project options

- assembly of 3 segments(parts)

- scanning of each individual part

- recording into company database

- work cycle time is 15 seconds

- supplemented by a printer and laser

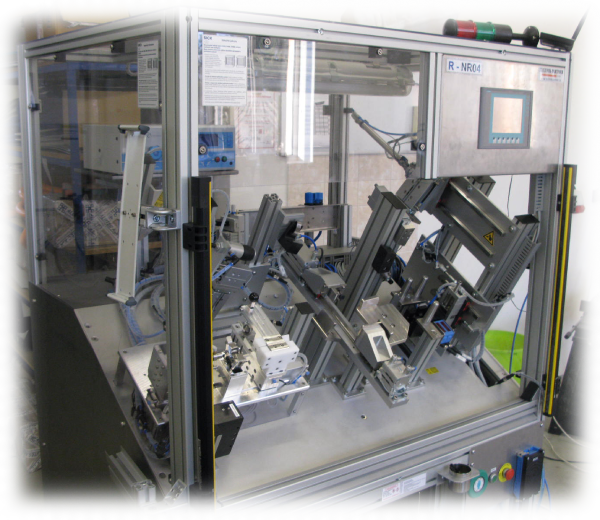

Final check- test station

Semiautomatic test station for final check of control switch (control button).Test runs on the carousel. Camera check(Cognex)-type of product, electric test of switch button. OK/NOK labelling done by inkjet printer. At the outlet of the device is manipulator for transfer of products to conveyor or reject part box(red-box). Control and measurements are executed by Analog PC cards.

EOLT Recliner-test station of recliner

- Bottom assembly: servo drive, gearbox, tensiometer for arm positioning and testing.

- Upper assembly: servo drive, gearbox, tensiometer on the access for recliner unlocking

- Tested part is automatically transferred to “remove” position after test

- camera test of product code

Work-Test station for assembly and leak test of windscreen washer fluid container.

Workstation for application of double-side adhesive tape on Flexprint for Daimler cars.

Workstation for assembly and final check of car washer fluid hose system.