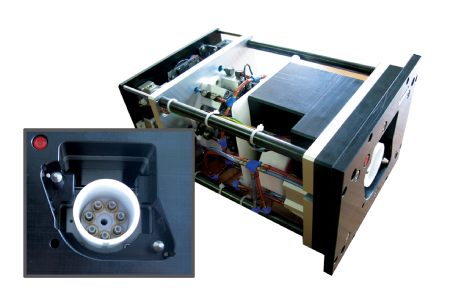

Section of test adapters designed for large production. The core of the adapter is pneumatic lock.

It is possible to integrate contact position control, control of secondary locks or additional elements control, leak test control, wire colour detection or form-shape control.

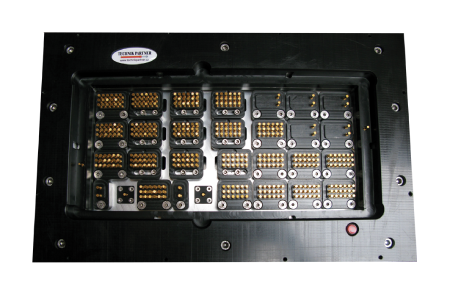

Push back system

Are used for the connectors when a “Catch test” is requested. In this kind of adapter, a defined force is applied to the stop parts in order to check correct seating inside the connector or to check that the connector is locked in position.

Zero-force

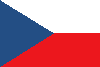

System where field with test probes pneumatically moves to contact position. It’s most useful and efficient when multiple- pin contact is necessary. One of the advantages is, that this system prevents, reduces operator fatigue and it can be combined with Push -back system.

Position Test by special geometry test probes

This system of control is based on predefined depth of countersunk test probe in connector body.

Special test probes are necessary for this kind of tests, where are options to define the correct height and diameter of test probe and diameter of support plate at the test probe.

Leak-test

System of vacuum/overpressure tests of seal at connector or connectors accessories. This test can detect missing od damaged sealing elements, eventually damage done at the main body.

By using the fine settings for air fulfilling pressure and air flow speed it is possible to manipulate the responsivity of test-control system. Compendious LCD display allows exact setting and control of test parameters and test conditions.