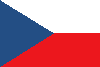

Cable harness workstation

Assembly and test workstation-workbench with independent control (build in test) and data evaluation. Cable harness testers and PLC automats are being used. Variety of detection tools can be used, for example cameras, sensors and optical devices and systems. All the detail and data needed or requested can be displayed on the command screen or display.

Assemble-Testing workstation for cable harnesses

Every cable harness is usually tested for cable and connector quality, cable conformity, cable functionality. Tests can be done by sensors or camera systems. System evaluates and signalize OK and NOK part. Each workstation and test-station is designed and assembled precisely according to customers specifications, included the height and angle (positioning) of workstations working table.

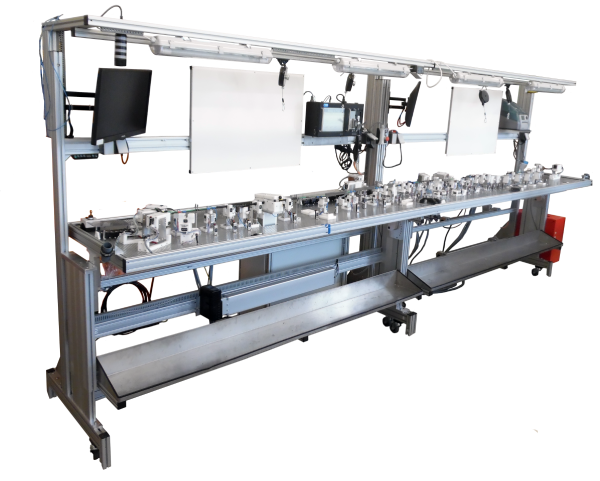

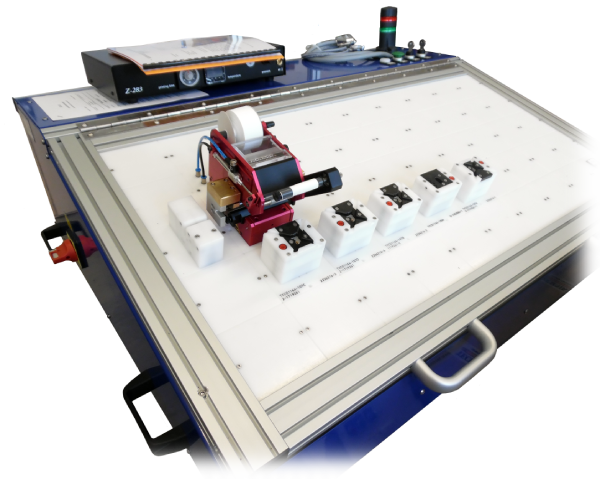

Compact testers and test benchstation

Compact bench testers of cable harness can be provided according to customers specifications as one purpose test bench, or multi-purpose with variety of pre-positioned adapters for different cable harnesses. Generally they are equipped with air distribution and connection, self-interface and “red-box” for NOK pieces. Control and evaluation is done by highly efficient testers, in small testing assemblies evaluation and control can be done by PLC with integrated screen panel.

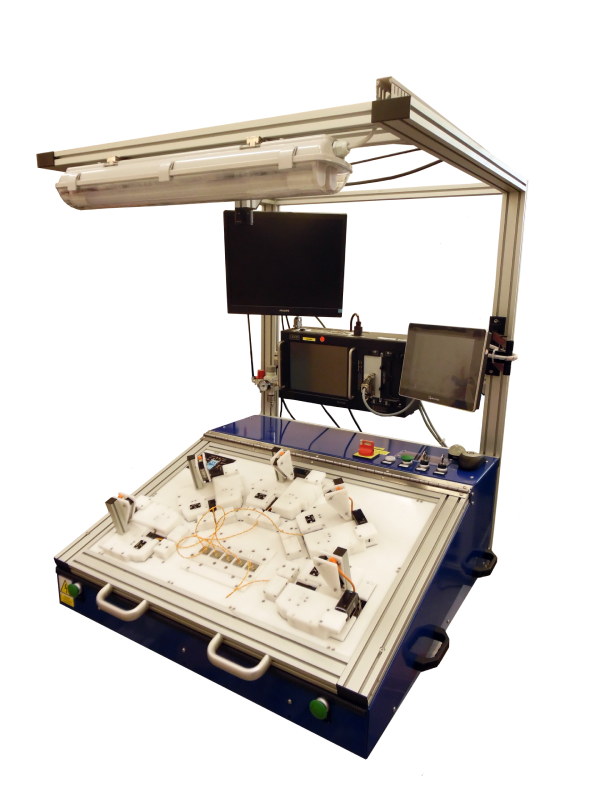

Other option when it comes to variety of the test system is “unit construction” system. This is a modular system with easy replacement of each module-adapter unit (male/female 180°, female 90°, one or two position connectors). Each module dimensions are 100mm ×100mm.Those systems allows electric and mechanical checks(continuity, short circuit, leak-seal test, cable conformity, cabling quality) Parts can be marked as OK by thermal printer ,NOK part can be cut in half or stay locked in the tester.

Ukázka dalších prací: